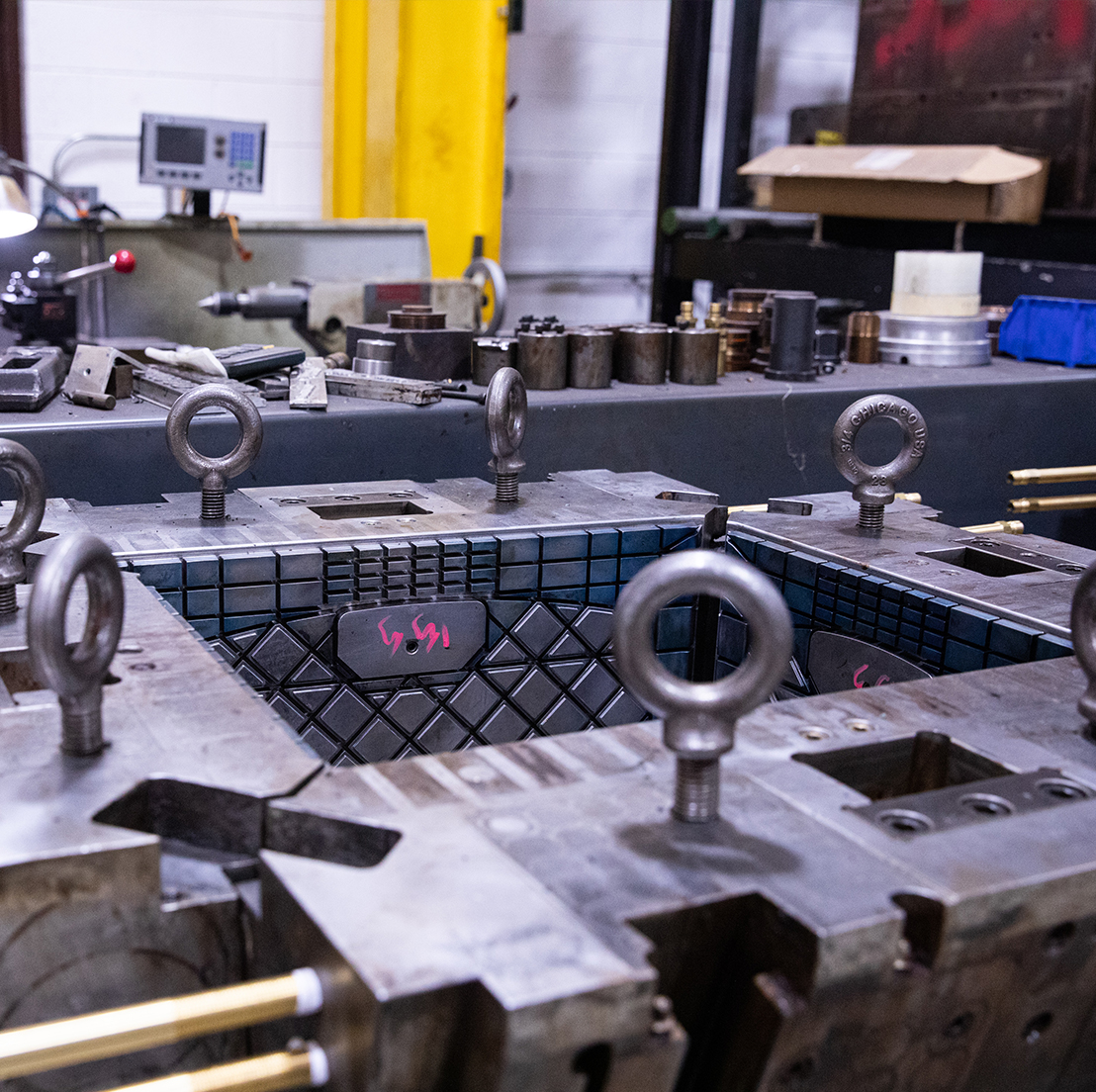

Our state-of-the-art engineering center and tool room bring your application from concept to mold, to final product. Rapid CAD engineering with FMEA analysis provides the manufacturing group with the necessary information for your custom part.

Over 80 injection molding machines provide the production capacity for the most demanding of applications. All IPCC machines are equipped with a detailed process monitoring system, IQMS, assuring our customers of the highest quality control standards and lowest manufacturing costs. IPCC uses IQMS to ensure all products are manufactured using the correct plastic resin and necessary additives.

Automation Ahead of Its Time

Automation at IPCC works hand-in-hand with each injection-molding machine. Direct interface (machine to robot) allows synchronous operation, allowing the robot to start a cycle while the molding cycle is ending.

IPCC Operations

- 250 Employees

- 5 manufacturing & assembly plants located in Lake Forest, IL

- Full-service tool repair shop

- Product design and engineering

- Tool design and engineering

- 80 operational molding machines; up to 3600 Metric Ton

- Warehousing and distribution

- 12 custom molder locations throughout North America

- Polypropylene and high density polyethylene recycling