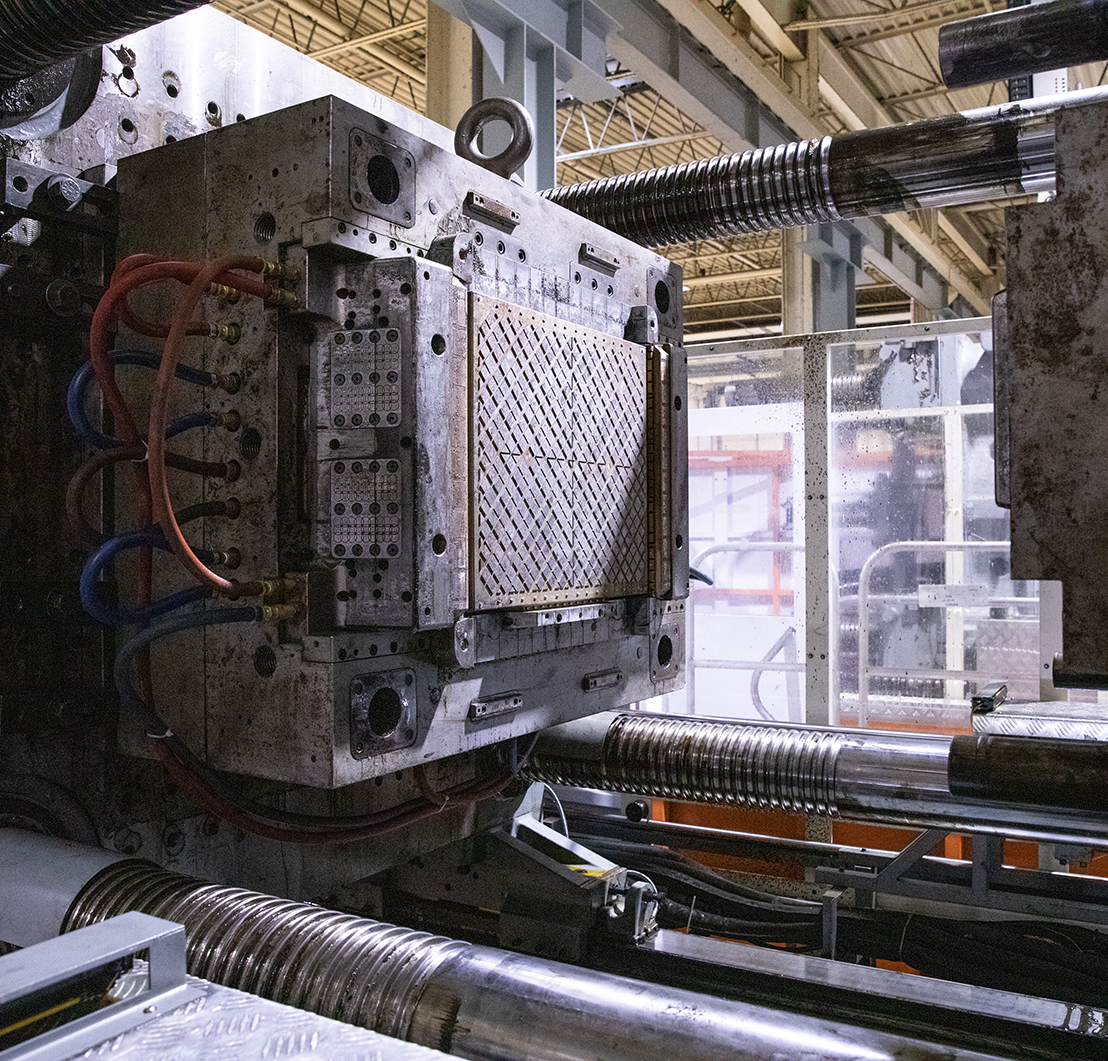

Over eighty presses provide molding capacity for the most demanding of applications.

Our 3600-ton injection molding presses are among the largest in North America. IPCC specializes in mid to large tonnage injection molding. This equipment distinguishes IPCC from most injection molding companies in the United States.

All IPCC machines are equipped with a detailed Process monitoring system, assuring our customers of the highest quality standards and lowest manufacturing costs.

Automation at IPCC works hand-in-hand with the injection molding press.

Direct interface (machine to robot) allows synchronous operation, allowing the robot to start a cycle while the molding cycle is ending. IPCC uses the latest generation of SEPRO robots to rapidly remove parts from our machines. The SEPRO robot is capable of handling parts over sixty pounds, moving at a rate of 2 meters per second. All robotic end-of-arm equipment creation and programming is performed in-house.

- Five manufacturing & Assembly Plants located in Lake Forest, IL (300,000 TOTAL SQUARE FEET)

- 250 Employees

- In-house mold manufacturing & maintenance

- Full service tool repair shop

- 80 operation molding machines ranging in tonnage from 55 tons through 1760 tons

- In-house warehousing and distribution

- 12 custom molder locations throughout North America

- Automatic Part Removal to be more cost effective

- 17 Silos to hold material in bulk and be more cost effective